What is Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a software application for warehouse operations used to manage and control the day-to-day activities in a warehouse or distribution center. It helps organizations efficiently manage their inventory, warehouse storage, and movement of goods within the facility. If you’re wondering what is Warehouse Management System, it’s essentially the digital backbone of modern warehouse operations.

The Warehouse Management System is the brain that controls everything inside a warehouse. It’s a warehouse automation software that helps businesses keep track of where items are stored, how they move around, and when they need to be shipped out. A WMS is like having a super-organized librarian who knows the exact location of every book (or every item in your warehouse!)

Core Functionalities of a WMS

📦 Receiving and Storing Goods

When new items arrive, the WMS helps workers know where to put them for efficient inventory storage and easy retrieval later. This ensures optimized warehouse space utilization and faster processing.

📊 Tracking Inventory

The WMS acts like a giant inventory tracking system. It knows exactly what you have in the warehouse, how much of each item, and where it’s located. This real-time inventory visibility reduces stock discrepancies and supports accurate demand forecasting.

🚚 Picking and Packing Orders

When a customer places an order, the WMS creates the best route for workers to quickly find the items and pack them up neatly. This improves order accuracy and speeds up warehouse fulfillment operations, especially for eCommerce logistics.

🚛 Shipping Orders

The WMS works with logistics carriers to figure out the fastest and cheapest way to get orders to customers. It also prints all the necessary shipping documentation and labels, ensuring smoother last-mile delivery management.

📈 Reporting and Data

The WMS collects a lot of information! It can tell you which items are selling well, if there are any warehouse process inefficiencies, and help you identify areas where you can save money and time using data-driven logistics strategies.

You Might Also Like To Read: Advanced Warehousing Technologies: 5 Latest Trends

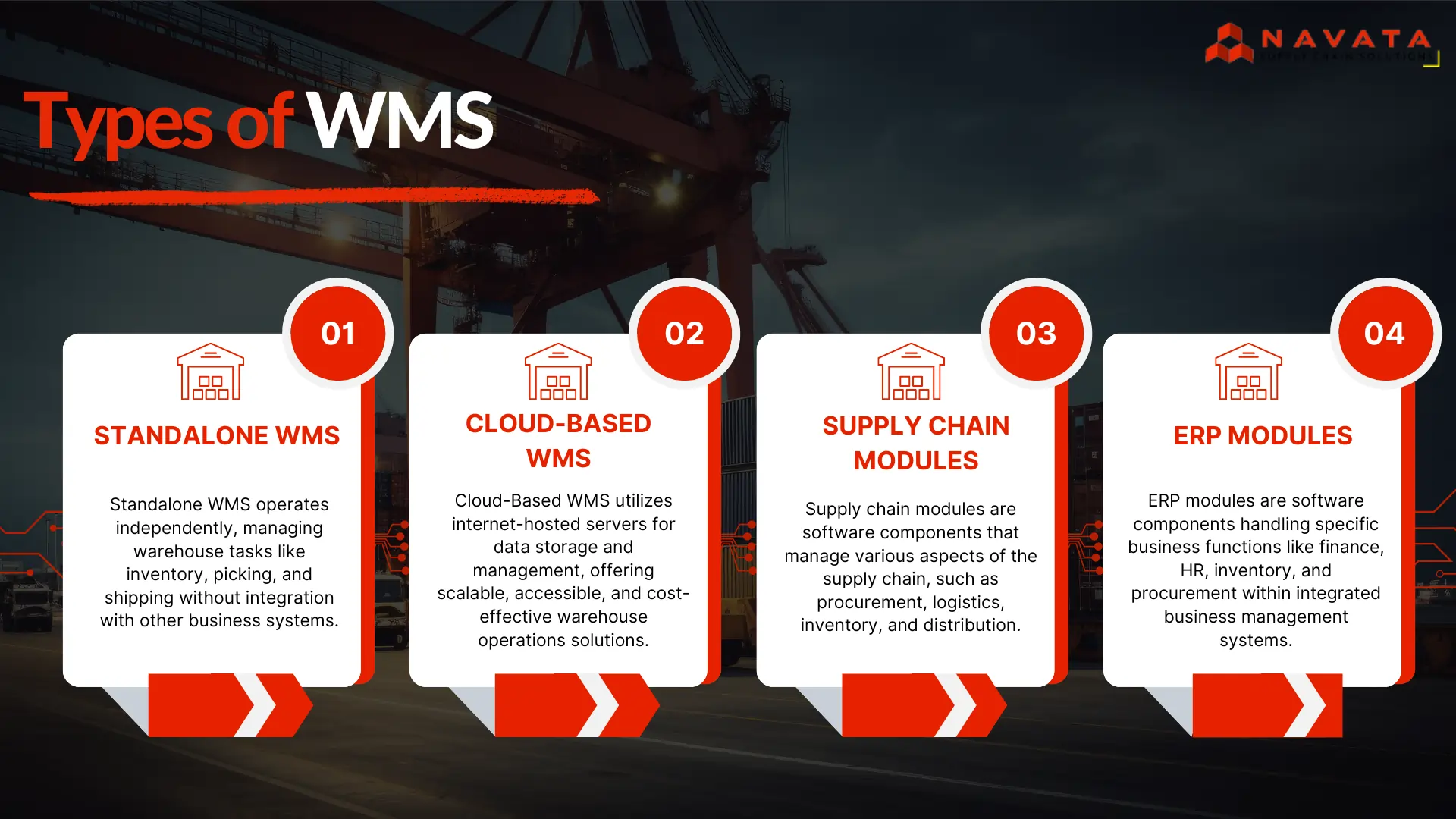

Types of Warehouse Management System

Warehouse Management System is essential software that streamlines your warehouse operations, from receiving new items to shipping them out to customers. But not all WMS systems are created equal! Let’s explore the different types to find the best fit for your business.

📦 Standalone WMS

A Standalone Warehouse Management System is like a traditional on-premise warehouse software program you install on computers within your warehouse. It focuses specifically on warehouse operations and might not connect directly with other business systems like accounting or order processing. This type of system offers in-depth warehouse management features and gives you full control. However, it can require upfront hardware and software costs, plus ongoing IT maintenance.

☁️ Cloud-Based WMS

A Cloud-based Warehouse Management System is like renting space for your inventory data and management tools in a giant online storage center (“the cloud”). You access it through a web browser from anywhere. This system offers quick deployment, no need to buy your own servers, and the provider handles software updates and data security. You usually pay a monthly subscription fee. On the downside, you have less control over customization and may rely on a strong internet connection for uninterrupted operations.

🔄 Supply Chain Modules

This type of WMS is built into a larger Supply Chain Management (SCM) software suite. The SCM handles a wide range of business processes, including warehouse management, transportation planning, and order fulfillment. A supply chain module provides a real-time view of your supply chain and helps coordinate activities beyond just the warehouse. However, it can be more complex and costly to implement than a standalone system.

🧩 ERP Modules

An ERP (Enterprise Resource Planning) system is designed to manage all aspects of your business, including finance, HR, and warehouse management. A WMS module within ERP keeps inventory tracking and data closely connected to other business functions. This gives you a unified data source across departments and improves interdepartmental communication. However, ERP systems tend to be large and complex, making implementation and customization time-consuming.

Which WMS is right for you?

The choice depends on factors like the size of your business, your IT budget, and how much integration you want with other systems. If you have any questions about these systems or need further advice, don’t hesitate to ask!

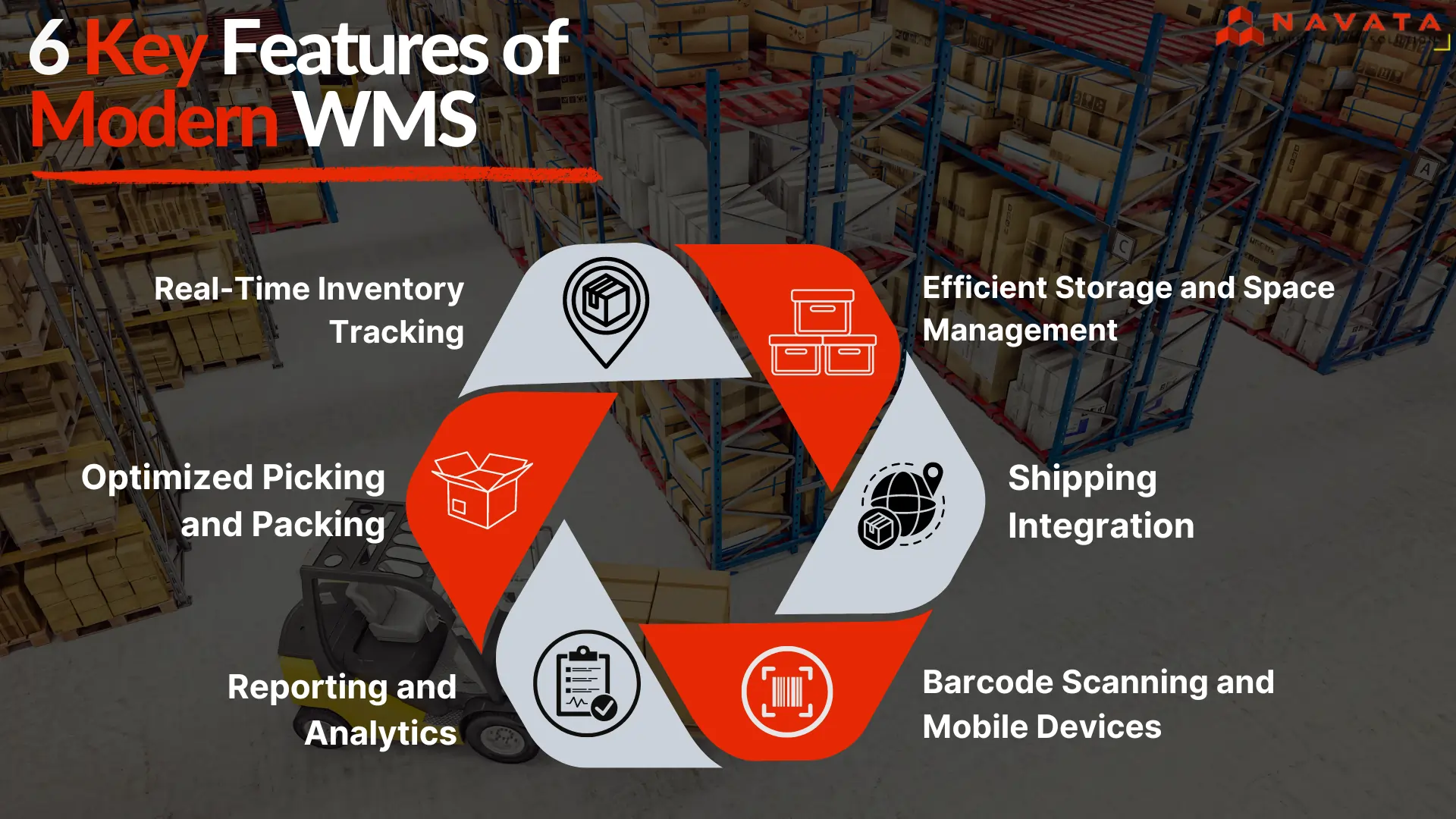

Key Features of Warehouse Management System

Real-Time Inventory Tracking

A modern Warehouse Management System (WMS) knows exactly what’s in your warehouse and where to find it at any given moment. Think of it like a super-accurate inventory map that updates itself constantly. This real-time inventory tracking helps prevent stockouts, reduces overstock, and improves order accuracy.

Efficient Storage and Space Management

The WMS helps you make the most of your warehouse space. It figures out the optimal storage locations so items are easy to find and your warehouse stays organized. This improves storage efficiency and reduces wasted space, a big win for warehouse optimization.

Optimized Picking and Packing

When orders come in, your WMS creates the fastest picking routes for workers to collect all the items and pack them securely for shipping. This leads to faster order fulfillment and improves pick-and-pack efficiency, ensuring on-time delivery and higher customer satisfaction.

Shipping Integration

The WMS communicates directly with shipping carriers to find the best rates and print labels with all the correct delivery information. This streamlines your shipping process, reduces manual errors, and supports multi-carrier shipping integration.

Barcode Scanning and Mobile Devices

Workers use barcode scanners and mobile WMS devices to interact with the system. This enables quick inventory checks, real-time order updates, and efficient item location tracking — all without piles of paperwork. It enhances warehouse mobility and boosts worker productivity.

Reporting and Analytics

A modern WMS collects large volumes of warehouse data and turns it into actionable insights. Through detailed inventory reports and performance analytics, businesses can spot patterns, fix inefficiencies, and make data-driven decisions that improve the supply chain workflow.

Bonus Features You Might Find

Automation Support

Some WMS systems support integration with warehouse automation technologies like conveyor belts, Automated Guided Vehicles (AGVs), or robotic picking systems to speed up processes and reduce human error.

Predictive Analytics

Advanced WMS solutions use predictive analytics and machine learning to forecast demand and suggest proactive inventory planning strategies. This ensures you’re ready for seasonal spikes or unexpected changes in consumer demand.

You Might Also Like To Read: 6 Latest Trends in Warehousing

Benefits of Warehouse Management System

Improved Inventory Accuracy

A Warehouse Management System (WMS) helps you track exactly what you have in stock, where it’s located, and when it needs replenishing. This reduces stockouts, overstocking, and costly errors, improving inventory control and supporting more accurate demand forecasting.

Increased Efficiency

A WMS optimizes how things move in your warehouse. It cuts down on wasted time and effort by creating efficient picking routes, streamlining packing workflows, and making it easier for workers to find the right items quickly—enhancing warehouse process efficiency.

Enhanced Labor Productivity

With real-time visibility and clear task assignments, warehouse workers spend less time searching and more time completing tasks. This boosts labor productivity, reduces idle time, and improves overall warehouse workforce performance.

Better Space Utilization

A WMS helps you maximize your existing warehouse storage capacity by recommending optimal storage solutions. This allows you to store more inventory without expanding your facility, reducing the need for extra warehouse rental costs.

Reduced Costs

The combined efficiencies from using a WMS help reduce labor costs, inventory holding costs, and shipping expenses. With optimized inventory management and carrier selection, businesses can lower operational costs while improving performance.

Improved Customer Satisfaction

With faster order fulfillment, fewer errors, and better on-time delivery performance, your customers enjoy a smoother buying experience. This leads to stronger customer loyalty, more positive reviews, and increased repeat purchases.

Data-Driven Insights

A WMS collects a wealth of operational data. By analyzing this warehouse performance data, businesses can identify trends, uncover process inefficiencies, and make smarter, data-driven supply chain decisions.

Read More About Benefits of Warehouse Management System

Make Supply Chain Your Competitive Advantage

Core Components of Warehouse Management System

Inventory Management

This is like keeping a really organized list of everything in the warehouse. It tells you what’s in stock, where it’s located, and how much of it you have. This enhances inventory visibility, helps avoid confusion, and ensures accurate inventory control, so you always know what’s available.

Order Management

Think of this as the system that handles customer orders. It ensures the right items are picked from inventory, packed correctly, and shipped on time. This process supports order accuracy, improves order fulfillment speed, and boosts customer satisfaction.

Receiving and Put-away

When new items arrive, this part of the system manages receiving operations and assigns the best place to store them. Efficient put-away processes lead to faster inventory turnover and optimized warehouse storage utilization.

Pick and Pack

This is about grabbing the right items from shelves to fulfill orders. Once picked, they are packed securely for shipping. Optimized pick and pack operations improve warehouse productivity and reduce order cycle time, ensuring timely eCommerce fulfillment.

Shipping and Manifesting

Once orders are packed, this part of the system handles shipment arrangement, label generation, and documentation. It ensures timely order dispatch, improves last-mile delivery efficiency, and simplifies carrier integration for cost-effective shipping.

Labor Management

This feature helps manage the workforce efficiently by assigning tasks smartly. It enhances warehouse labor productivity, reduces idle time, and improves overall operational efficiency through intelligent labor resource allocation.

Reporting and Analytics

This provides deep insights into warehouse performance. It delivers data-driven reports to help managers track KPIs, identify bottlenecks, and make informed decisions. WMS analytics support continuous improvement and better supply chain visibility.

Read More About Core Components of Warehouse Management System

Thanks For Reading: What is Warehouse Management System (WMS)?

Powered By 360Presence

1 Comment